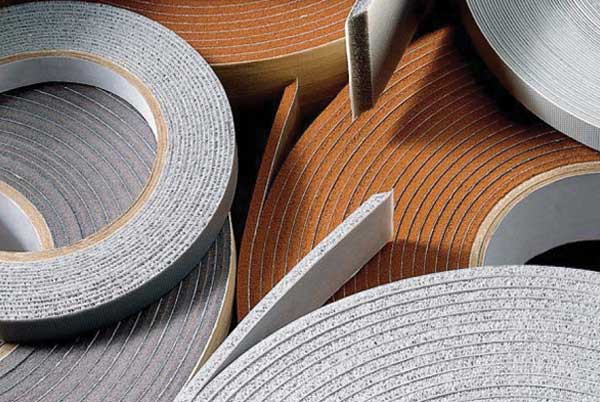

PEEL-N-STICK Silicone Rubber Adhesive Tapes

PEEL-N-STICK is the trade name for the HPP family of silicone rubber tapes. For extreme temperature applications, PEEL-N-STICK silicone rubber tapes out-perform all other elastomers in service life, weather-ability, compression set resistance and electrical resistivity.

An HPP Product Series

- Easy to apply

- Compressible and flexible

- Conforms to irregular shapes

- Eliminates die cutting

- High adhesion to stainless steel, plastics, aluminum and composites

- Low compression set

- Available in closed-cell sponge, low density foam or solid rubber

Applications

These pressure sensitive PEEL-N-STICK tapes are available in a variety of widths and thicknesses for use in gasketing, cushioning, thermal insulation and vibration dampening applications. Other uses include noise reduction, clamping of hot parts and electrolysis reduction between dissimilar metals. PEEL-N-STICK tapes, which provide all the benefits of silicone rubber in an easy-to-apply, pressure-sensitive tape form, are available in standard stock widths or slit to order.

Styles Available:

Type HP100S: Silicone Sponge with a high temperature silicone adhesive.

Type HP200A: Silicone Sponge with an aggressive acrylic adhesive.

Type HP200A: Silicone Sponge with an aggressive acrylic adhesive.

Type HP300AR: Reinforced Silicone Sponge with an aggressive acrylic adhesive.

Type HP440S: Combines a 30 durometer solid rubber with a high temperature silicone adhesive.

Type HP400A: Combines a 30 durometer solid rubber with an acrylic adhesive.

Type HP512AF: Uses fire-blocking foam along with a film-supported acrylic pressure sensitive adhesive.

Type HP400A: Combines a 30 durometer solid rubber with an acrylic adhesive.

|

Physical

Properties |

Unit of Measurement |

Sponge HP100S |

Sponge HP200A |

Sponge Reinforced HP300AR |

Solid HP440S |

Solid HP440A |

Foam HP512AF |

ASTM Test Method |

|

Adhesion

to Steel* |

Oz./in (gm/cm) |

15 (168) |

30 (335) |

30 (335) |

15 (168) |

30 (335) |

30 (335) |

D1000 |

|

Compression Deflection |

Psi (Kpa) Compressed to 75% of

original thickness |

6-14 (41.3-96.5) |

6-14 (41.3-96.5) |

8-16 (55.1-110.2) |

40-50 (275.6-344.5) |

40-50 (275.6-344.5) |

1-5 (6.89-34.6) |

D1056 |

|

Tensile

Strength |

Psi (Mpa) |

65 (.448) |

65 (.448) |

100 (fabric break, ppi) (17.9kg/cm) |

700 (4.82) |

700 (4.82) |

20 (film break, ppi) (3.6kg/cm) |

D412 |

|

Elongation |

% |

150 |

150 |

<10 |

650 |

650 |

75 |

D412 |

|

Compression

Set |

% (compressed 50% for

22hrs. @ 212°F) |

25 |

25 |

25 |

30 (compressed to 75% of

original thickness) |

30 (compressed to 75% of

original thickness) |

5 |

D1056 |

|

Density

of Backing |

Lb/in³ (g/cc) |

.019 (.526) |

.019 (.526) |

.020 (.554) |

.040 (1.11) |

.040 (1.11) |

.007 (.194) |

D3574 |

|

Silicone

Rubber Material Type |

__ |

Sponge |

Sponge |

Reinforced Fiberglass

sponge |

Solid |

Solid |

Foam |

__ |

|

Adhesive

Type (with

release liner) |

__ |

Silicone |

Acrylic |

Acrylic |

Silicone |

Acrylic |

Acrylic |

__ |

|

Color |

__ |

Orange |

Orange |

Blue |

Gray |

Gray |

Gray |

__ |

* Adhesive shelf life when stored at 70 F (21 C) to 90 F (32 C) at less tan 50% humidity:

Silicone adhesive on sponge – 6 months; silicone adhesive on solid – 1 year; acrylic adhesive on sponge or solid – 2 years.

To maximize shelf life, store at 40 F (44 C) to 50 F (10 C).

Availability:

Special order, minimum quantity.

Thickness tolerance for backing only.

|

Thickness / in. |

Tolerance***/

mm |

HP100S |

HP200A |

HP300AR |

HP440S |

HP440A |

HP512AF |

Roll Length Yards / mm |

|

1/32

+/- .010 |

(0.79 +/- .13) |

|

|

|

__ |

__ |

|

20 (18.2) |

|

1/16

+/- 1/64 |

(1.59 +/- .41) |

__ |

__ |

__ |

|

|

__ |

10 (9.1) |

|

3/32

+/- 1/64 |

(2.38 +/- .41) |

__ |

__ |

* * |

|

|

* * |

10 (9.1) |

|

1/8

+/- 1/32 |

(3.18 +/- .79) |

__ |

__ |

__ |

|

|

__ |

10 (9.1) |

|

3/16

+/- 1/32 |

(4.76 +/- .79) |

__ |

__ |

__ |

|

|

__ |

5 (4.6) |

|

¼

+ 3/64 – 1/32 |

(6.35 +/- 1.19 - .79) |

|

|

|

|

|

__ |

5 (4.6) |

|

Min.

widths, in (mm) |

|

½ (12.7) |

½ (12.7) |

¼ (6.35) |

½ (12.7) |

½ (12.7) |

½ (12.7) |

__ |

Important notice to Purchaser: The following is made in lieu of all warranties, express or implied. Sellers and manufacturers only obligation shall be to replace such quantity of the product found to be defective. Neither seller nor manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use of or the inability to use the product. Before using, user shall determine the suitability of the product for its intended use, and user assumes all risk and liability whatsoever in connection therewith. The foregoing may not be changed except by an agreement signed by officers of seller and manufacturer. Specifications are subject to change without notice.

Cell Size: Silicone Sponge products may show variations in cell size. This is not cause for rejection if HPP finished product standards are met

PEEL-N-STICK Dimensions: Upon removal of the liner, the potential exists for dimension changes as the sponge relaxes.