Jerky Screens

Hi-Performance Products offers a wide variety of specialty screening materials that were specially formulated for use in the Jerky Processing Industry, to eliminate jerky products from sticking to stainless steel racks.

PTFE Coated Fiberglass

(500°F Service Temp)

PTFE COATED GLASS

PTFE STAINLESS STEEL

Polyethylene Screen

(200°F service Temp)

PTFE COATED GLASS

PTFE FILM

Polypropylene Screen

(220°F Service Temp)

PTFE COATED GLASS

PTFE FILM

ROTARY SEALING BANDS • BAR SEALING TAPE & BAR SEALING FABRIC

USDA-Approved Teflon Coated Fiberglass:

Smokehouse non-stick screens that offer superior release, flexibility, dimensional stability and thermal resistance. Sealed edges included.

| Part Number | Mesh Size | Screen Size | Color |

| TJS-316 | 3/16" | Custom | . |

| TJS-140 | 1/4" | Custom | . |

| TJS-516 | 5/16" | Custom | . |

UFDA-Approved HD Polyethylene:

Smokehouse non-stick screens made from High Density Polyethylene Resin that offers a softer, more flexible plastic screen product.

| Part Number | Mesh Size | Size | Sun Yellow | Clear | Yellow | Black |

| PJS-12HDPE | 1/2" | Custom | Royal Blue | Aqua | Green | Sky Blue |

| . | . | . | Lilac | Wild berry | Rasberry | Pink |

| . | . | . | Orange | Mauve | Dark Red | Peach |

FDA-Approved Polypropylene:

Polypropylene resin that offers enhanced non-stick properties and the ability to withstand higher temperatures than our Polyethylene Smokehouse Netting.

| Part Number | Mesh Size | Size | Sun Yellow | Clear | Yellow | Black |

| PJS-12HDPP | 1/2" | Custom | Royal Blue | Aqua | Green | Sky Blue |

| . | . | . | Lilac | Wild berry | Rasberry | Pink |

| . | . | . | Orange | Mauve | Dark Red | Peach |

Hi-Performance Products, Inc.

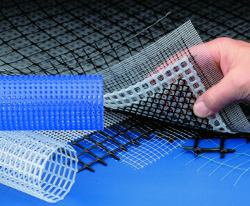

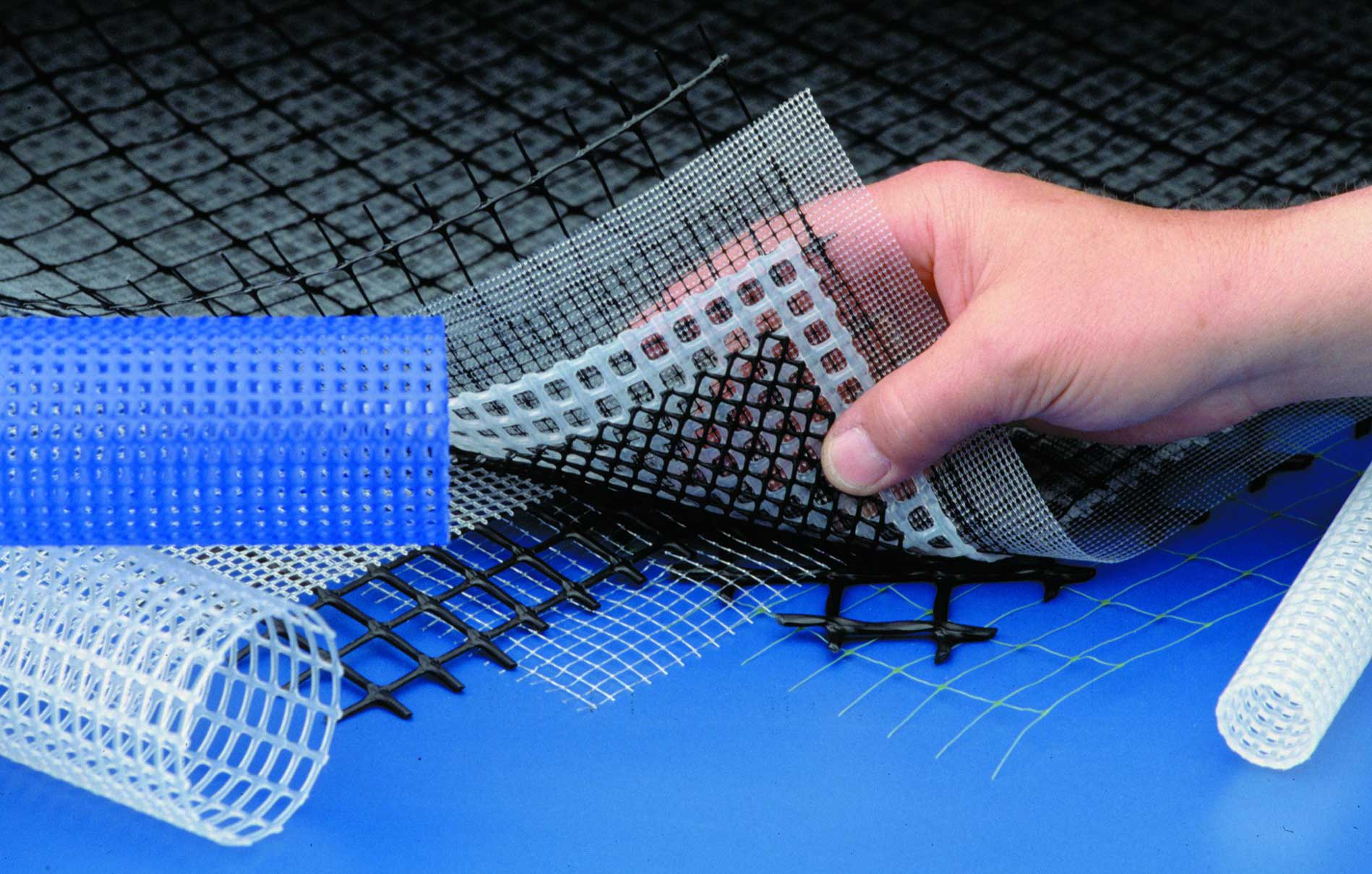

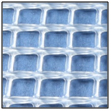

HPP FDA Compliant Square Jerky Screens

The joint structure of plastic square mesh screens is quite different from extruded plastic diamond mesh screening. Machine direction strands run the length of the roll and cross direction strands run the width of the roll.

Joints are formed at the intersection and are not stacked one over the other as in diamond mesh plastic netting.

Generally, the machine direction strand is thicker than the cross direction strand. The overall thickness of the netting is typically determined by the machine direction strand thickness. As a result of this joint configuration, plastic square netting usually has one side of the material that is smooth, that is, both the machine and cross strands are flush on the same plane, and one side that is “bumpy”, where the machine direction strand has a higher profile than the cross strands. So customers can choose from a smooth or textured transfer pattern.

Square mesh plastic netting is extruded in a wide range of configurations featuring:

- Structural integrity

- Apertures “locked” by fused joints

- Smooth surface on one side

Most products from HPP are available in bulk rolls or custom cut sizes. Choose from a broad range of apertures and thicknesses or consult with an HPP representative to help identify a specific product for your intended use.

Square Mesh Styles

PJS12DHPEY

.275” x .275”; .500” x .500”

PJS12HDPEN

.25” x .25”

PJS275PPB

.275” x .297”

PJS275PPN

.275” x .297”

PJS282PPN

.282” x .274”

PJS300PPN

.300” x .280”

PJS75PPN

.75” x .75”

Custom

your specs